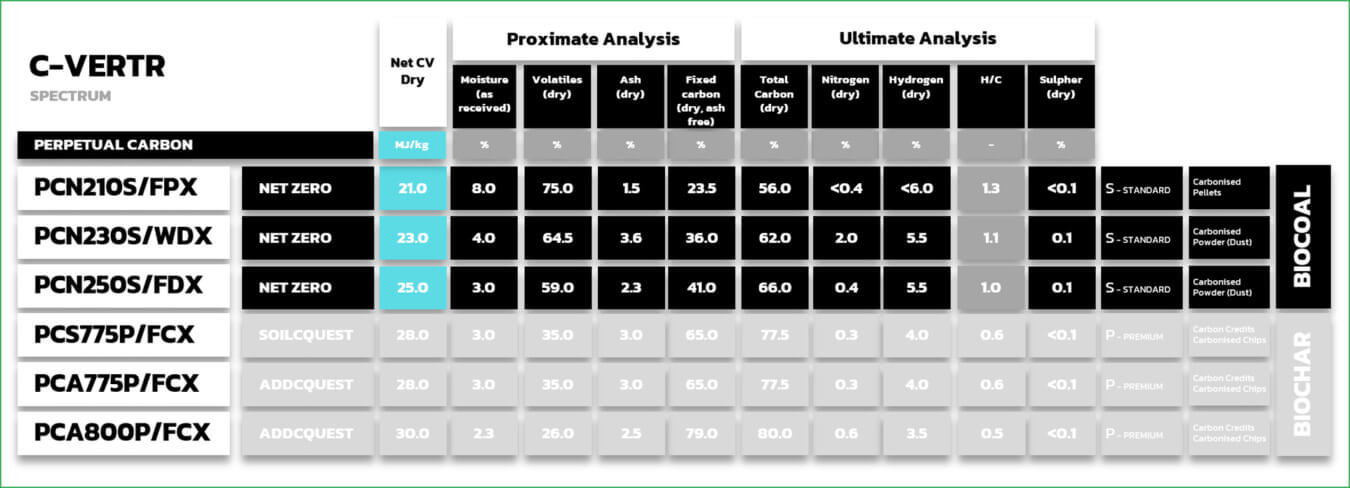

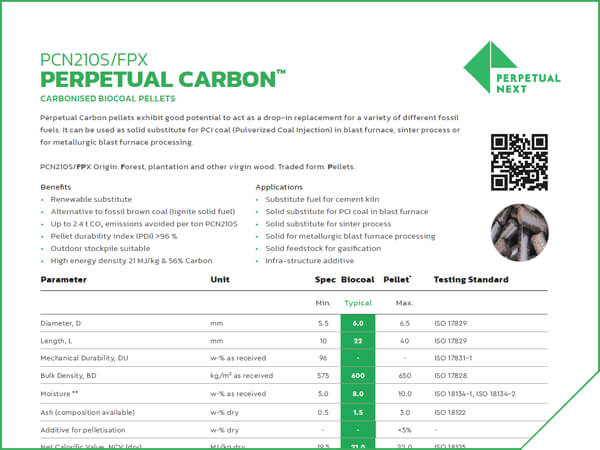

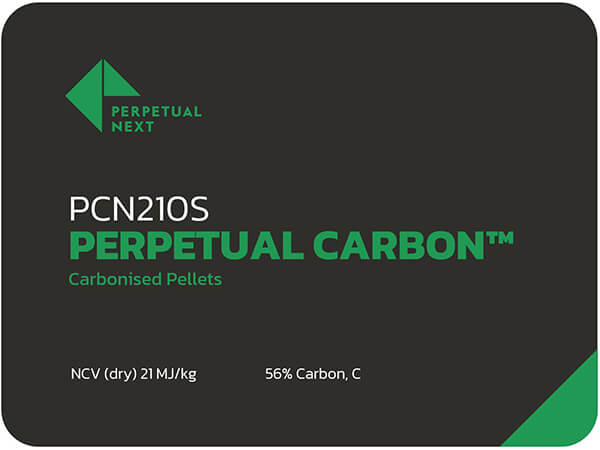

PCN210S/FPX

Origin: Forest, plantation and other virgin wood.

Traded form: Pellets

Perpetual Carbon pellets exhibit good potential to act as a drop-in replacement for a viarity of different fossil fuels. It can be used as solid substitute for PCI coal in blast furnace, as a substitute for sinter process or for metallurgic blast furnace processing.

Benefits

- Renewable substitue

- Alternative to fossil Brown coal (lignite solid fuel)

- Up to 2.4 t CO₂ emissions avoided per ton PCN210S

- Pellet durability index (PDI) >96 %

- Outdoor stockpile suitable

- High energy density 21 MJ/kg & 56% Carbon, C

Applications

- Substitute fuel for cement kiln

- Solid substitute for PCI coal in blast furnace

- Solid substitute for sinter process

- Solid for metallurgic blast furnace processing

- Solid, feedstock, for gasification

- Infra-structures additive