25 juni 2024

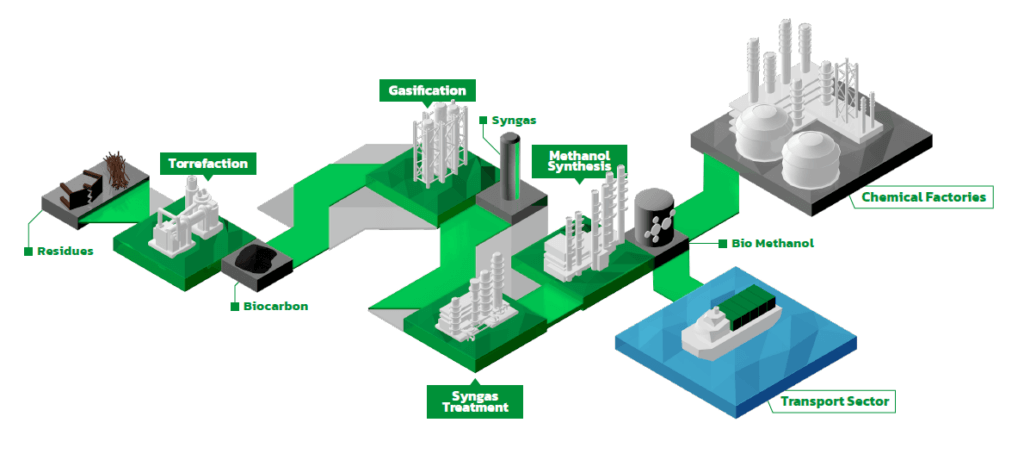

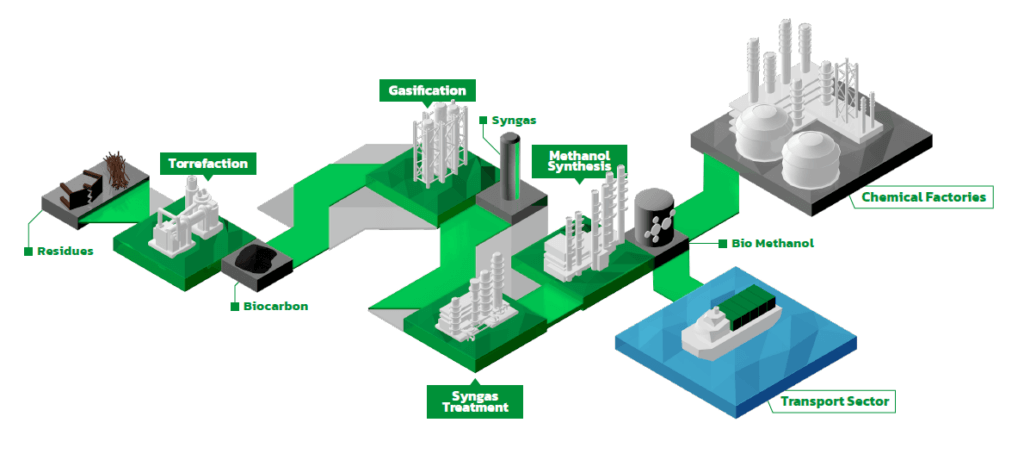

Syngas is essential in many industrial processes that use it as a feedstock to build molecular structures that end up in many of our day-to-day products. There are different ways to create syngas from gasification. The traditional methods are to gasify fossil coal or steam reforming. This involves reacting a hydrocarbon fuel (like natural gas) with steam at high temperatures. It's a widely used method. In order to move away from fossil and reach net zero objectives, different approaches have been developed which involve various methods to convert the renewable carbonaceous content of waste streams into syngas. Perpetual Next converts organic waste streams into biocarbon, that can mimic fossil coal properties. A good understanding of these properties and characteristics is essential to make biocarbon meet the requirements of the gasification process.

Fossil carbon

A little bit of background on fossil carbon. Millions of years ago, Earth looked quite a bit different than today. Swampy forests thrived. And when these plants died, they didn't fully decompose due to the lack of oxygen in the swampy environment. When time passed these organic remains became buried under layers of sediment like mud and sand. The weight of these layers built up and pressed down on the buried plant matter.

As more and more sediment gathered, the temperature and pressure on the buried plant material increased. This resulted in a slow and intense cooking process which prevented complete decomposition and started transforming the plant matter into coal.

The amount of heat and pressure determines the type of coal formed. Lignite, or brown coal is the least compressed and youngest type of coal with a lower carbon rate. While anthracite, black coal, is the most compressed and oldest, containing the highest amount of carbon. Black carbon burns hotter, more efficient, than brown coal.

So, the black coal we use today in our industry is essentially the preserved remains of ancient plants. It is biomass that has undergone a long process of decomposition under high pressure and temperature in a low oxygen environment.

Torrefaction

Where it takes mother nature millions of years to form this fossil coal, Perpetual Next can carbonize organic residues to biocarbon in a matter of hours. With our carbonization technology (torrefaction) we convert organic waste into biocarbon that can meet the same properties as fossil coal.

Coal gasification to create syngas

Fossil coal gasification has been applied since the18th century. Coal was heated in the absence of oxygen to produce gas for lighting and heating homes and streets. In the mid-20th century this method became less popular because of the discovery of natural gas and the construction of a pipeline network for distribution of the gas. Natural gas offered a cleaner and more efficient alternative, leading to the decline of coal gas production for most applications.

The discovery and depletion of natural gas reserves, coupled with concerns about air pollution from coal combustion, have led to a renewed interest in coal gasification. Today, coal gasification is primarily used to produce "synthesis gas" (syngas), a mixture of hydrogen and carbon monoxide. This syngas can be used as intermediate to produce several hydrocarbons and is in some cases still used to generate electricity in cleaner and more efficient ways compared to traditional coal burning. The syngas can be used as a raw material for various industrial chemicals like methanol.

Biomethanol

Bio methanol is considered a sustainable replacement to grey methanol (derived from natural coal or gas) because it is produced from renewable sources, and it has a significantly lower carbon footprint compared to fossil fuel-derived methanol. Bio methanol can be produced from syngas produced by gasification of biocarbon.

Torrefaction as an ideal pretreatment for gasification

In order to gasify biocarbon, it has to mimic fossil coal properties. A good understanding of these properties and characteristics is essential to make biocarbon meet the requirements of gasification technology.

For example, for gasification uniform particles are needed. In fossil coal this effect of uniformity in particles is seen ‘naturally’. In biocarbon it isn’t found naturally so we found a way to mimic these properties in order to enable gasification of biocarbon through conventional gasification technology.

Perpetual Next’s approach to creating biogenic synthetic molecules leverages a combination of multiple proven technologies, enhancing the reliability of our projects. This reliability is further bolstered by employing high gasification temperatures, which prevent tar issues in downstream units. Additionally, many tars occurring in thermal conversion processes are removed during the upstream torrefaction process.

Perpetual Next is fully committed to deliver bio methanol in the coming years. With two large scale production facilities already in development with a combined capacity of 440,000 tons per annum.