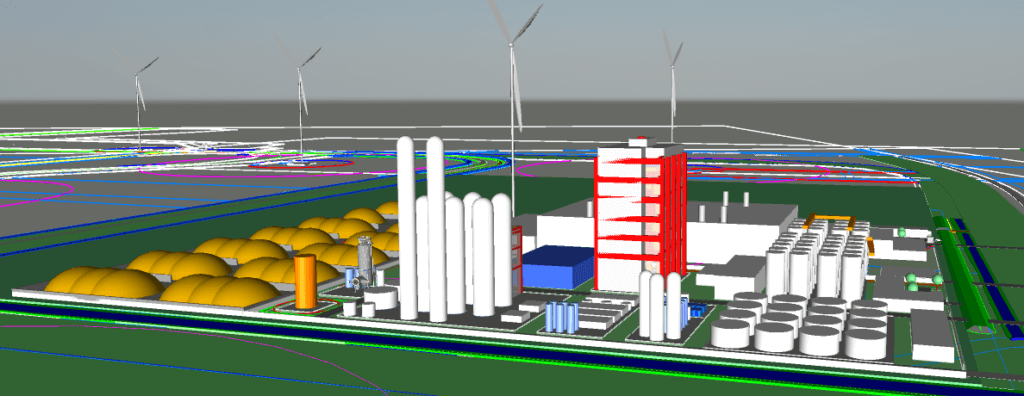

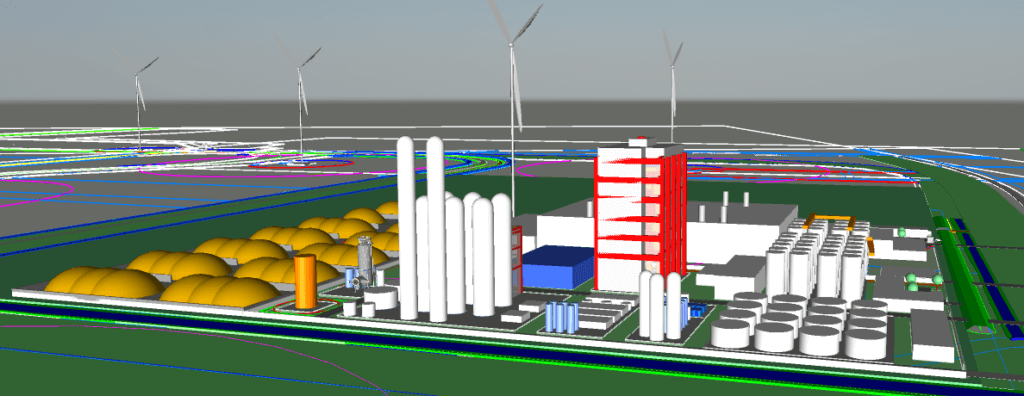

In the Eemsdelta in Delfzijl The Netherlands, Perpetual Next owns a 16ha plot. This is one of the few remaining so called ‘category 5’ plots meaning industrial development is allowed. Perpetual Next is developing its biomethanol blueprint that will play a major role in making the chemical- and maritime industry more sustainable.

Intensified legislation pushes the market towards sustainability. This includes measures like The EU-ETS Emission Trading System currently in place. And the Maritime sector is also included in the sustainability goals as of 2024 driving up the demand for biomethanol way beyond production capacity. The orderbook of methanol-capable vessels has more than doubled since 2022; the overwhelming majority of these vessels are container ships. In other words, major container lines are banking on green methanol as a key element for decarbonizing their operations,

DeltaTorr

Perpetual Next uses carbonization (torrefaction) as a pre-treatment of biomass to produce biocarbon as a feedstock for conventional gasification processes. Perpetual Next’s knowledge of- and unique experience with carbonisation (torrefaction) technology makes the company a one-of-a-kind system to produce high quality biocarbon based on a wide range of organic waste streams. Where it takes nature millions of years to form fossil coal, we can carbonise this residue to biocarbon in a matter of hours. Thanks to years of research and experience we’ve managed to tailor biocarbon properties to mimic fossil coal.

The DeltaTorr carbonisation plant will have a capacity of producing 350.000 t/a biocarbon.

DeltaNor

Gasification is a technological process that can convert carbon-based raw material such as coal into synthesis gas (syngas for short). Gasification is traditionally done with fossil coal. Using organic waste streams is much more sustainable since the CO₂ generated in bio-energy production is equal to the CO₂ absorbed during the growth of the waste streams.

Perpetual Next’s biocarbon properties can mimic fossil coal. This allows our biocarbon to meet the narrow inlet requirements of the gasifier. This enables the application of commercially available, widely proven, conventional gasification technologies, like entrained flow.

DeltaNor is developed for a capacity of 220.000 t/a biomethanol produced from biocarbon produced by DeltaTorr. Both plants are located on the same 16ha plot.