Our chemical industry forms an essential link in the production of various important products: indispensable in our daily lives. From food to medications to plastics: chemistry plays a vital role in society.

The chemical industry can be one of the greatest contributors to CO2 reduction. About 14% of the world oil production and 8% of the extracted natural gas is now used in this industry and is now mainly used as fuel. This means it is used as energy to create products by transforming raw materials with chemical processes. And it is used as a raw material for example carbon atoms.

Upgrading residual materials is key to meet the demand for decentralised renewable products. Carbonisation enables the production of a highly homogeneous material of a constant quality, which is used as raw material for chemical processes, like bio-refinery. Splitting syngas into the basic building blocks for applications in the chemical industry through cracking and extraction processes.

Do you want to work with us on a new industrial revolution? Transform the chemical industry in a circular and fossil free industry? Let's connect

Carbonisation will become tomorrow’s most popular working horse for mobilising bioresidues, fully closing the carbon cycle for our materials, fuels and fertiliser needs

- Marijn Rijkers, Program Director Biobased and Circular Economy at InnoSyn

Do you work with chemical processes? And do you rely on raw materials that are carbon-dense? We can enable you to become circular and fossil free.

In the transition from traditional emission-intensive production to Net Zero, important decisions need to be made. We understand the complexity of assessing the options to accelerate your roadmap to Net Zero. Introducing renewable carbon to your process can represent a key element on your roadmap to fossil free chemical processes.

Our renewable carbon products are developed and produced from biologic low-grade waste streams, such as demolition wood and forestry and agricultural residues. Wood and residues that can no longer be used for any other purpose.

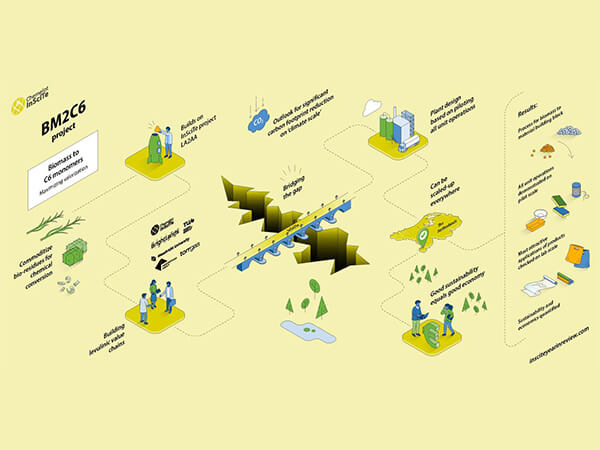

The BM2C6 project in which we participate, works on developing a new value chain from biomass to C6 monomers. By means of the BM2C6 project we aim to create an unprecedented value chain starting from carbonised biomass (biocarbon) up to C6 monomers.

The road from biomass to C6 monomers has many different process steps. This includes application testing of all products and co-products. It all starts with levulinic acid (LA), produced from woody biomass. Levulinic acid is recognised as a major stepping stone to ‘green’ a wide range of down-stream solutions. Moreover, its high carbon yield and energy yield ensures excellent sustainability and process economics.

Perpetual Next produces syngas (green gas) by carbonising and gasifying, bio residual flows. Green gas is a CO2-neutral gas. Green gas can be supplied to chemical companies as a source for biobased chemicals.

The chemical industry is seeking alternatives for fossil-based products to achieve the climate targets. InSciTe contributes to the development of products and intermediates with a reduced environmental footprint both in commodity and specialty applications.

Example of a Perpetual Carbon project

All process steps will be demonstrated on pilot scale. This project is expected to show both ecologix and economic benefits for the entire value chain. This will showcase the wide range of opportunities to industrial partners. And we invite them to step in and differentiate themselves in sustainable activities.

We seek to understand your process and your challenges. Thanks to our dedicated R&D specialist team we continuously push the boundaries of product development, that we test on industrial scale. We provide new solutions in the form of renewable carbon products and renewable carbon technologies for different production processes.

Carbonisation and gasification enable the production of a highly homogeneous carbon product constant quality, which is used as raw material for chemical processes, like bio-refinery, further gasification and pyrolysis.

Organic residues to biocoal

In Vägari, Estonia, a biocoal plant based on Perpetual Next's C-Vertr V technology has been under construction since 2020. A total of eight to ten reactors will be installed in the plant, capable of producing 120 kilotons of biocoal per year.

Organic residues, B-wood & SRF to biocarbon

In Dilsen-Stokkem, Belgium, a biocoal plant based on Perpetual Next's C-Vertr R technology has been in operation since 2010. This site has a design capacity of 27,700 t/y of biocoal output.

This section contains a selection of our most relevant technical papers in the field of carbonisation for this segment application. These technical papers are mostly papers from our own Perpetual Next experts.

For all our technical papers, please visit our Knowledge page.

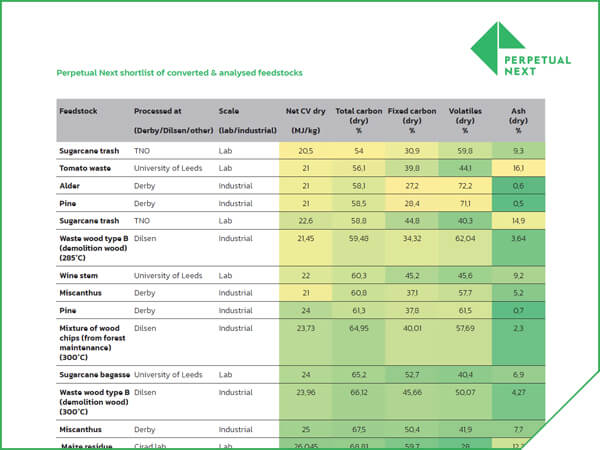

Tabel

At Perpetual Next, we continue to analyse different types of feedstocks, options from different feedstock baskets, with different properties. All feedstocks have their advantages, it all depends on which bias you look at an opportunity. This document is the shortlist of feedstocks we have looked at so far in more detail.

This section contains a selection of the most relevant scientific papers in the field of carbonisation for this segment application. These scientific papers are made by scientist in the field of carbonisation. So these downloads are conducted by others.

For all our technical papers, please visit our Knowledge page.

Daniela Thran, Janet Witt, Kay Schaubach, ...

The large-scale implementation of bioenergy demands solid biofuels which can be transported, stored and used efficiently. Torrefaction as a form of pyrolysis converts biomass into biofuels with according...

Q.R.B. Broxterman, M.C.C. Janssen, M.P.W.M. Rijkers

Renewable feedstock offers magnificent business development opportunities in chemicals and materials. We describe the emerging Levulinic Acid (LA) product tree, with woody biomass as a raw material...

Marijn Rijkers

What it takes to make it happen.

ECRN regions' bioeconomy projects.

Chemelot Institute for Science and Technology (InSciTe).

This section contains our position papers. These position papers are documents that present an arguable opinion in the field of carbonisation.

For all our technical papers, please visit our Knowledge page.

How Perpetual Next leads the emerging carbon removal industry

Greenhouse gas emissions are caused by human action and also by nature itself. It is mainly the exhaust gases from the combustion of fossil fuels that pollute the atmosphere with carbon that was previously stored in...

Part of discussion artickels about carbonisation of low-value bio-residual flows for replacement of fossil carbon

Nowadays it is widely accepted that the era of fossil carbon must end and therefore an important and urgent transition to a fossil-free industry needs to take place. Carbonised solids are perhaps the most known ...

External paper

Lime and limestone are basic enabling compounds which are necessary to many other industrial value chains, such as air pollution control, purifying drinking water, wastewater, support sustainable agriculture, enable...

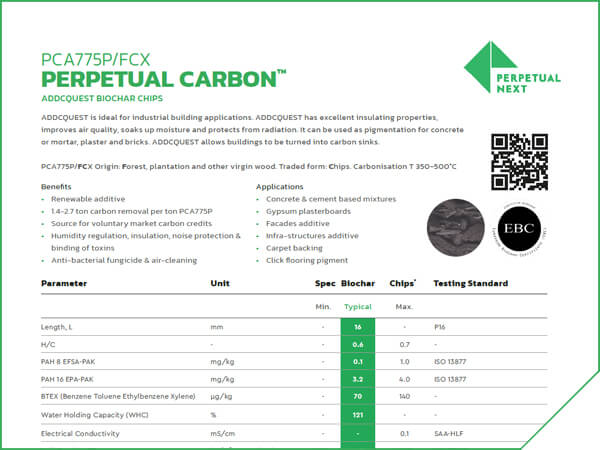

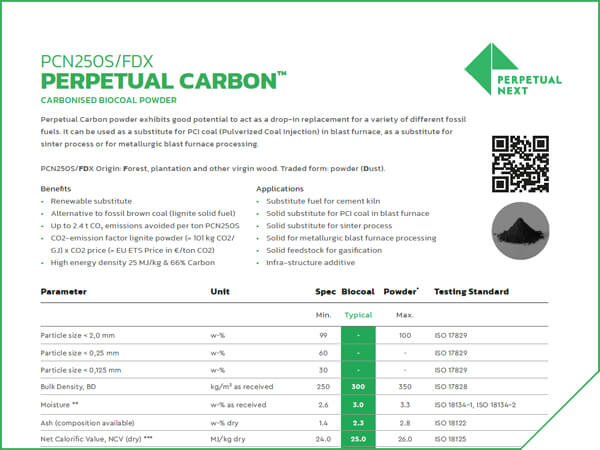

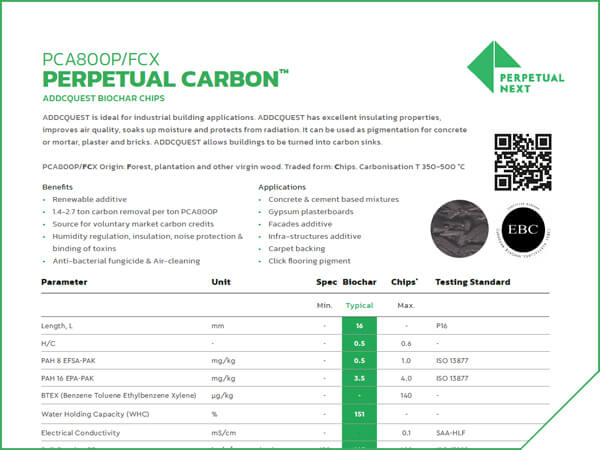

This section contains a selection of our specification (spec) sheets. A spec sheet, or data sheet, summarizes the performance and other characteristics of a specific form and grade of Perpetual Carbon.

For all our technical papers, please visit our Knowledge page.

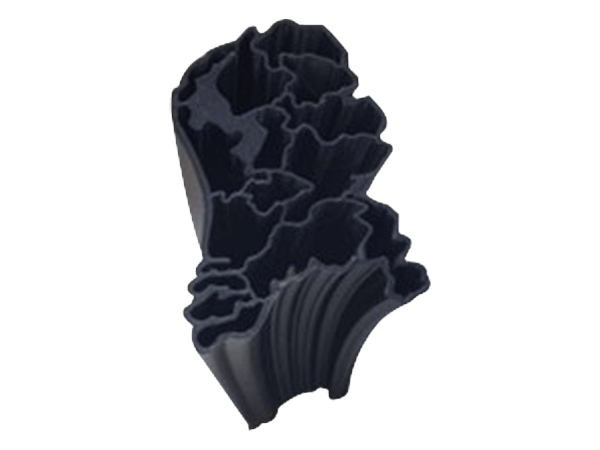

AddQuest biochar chips

ADDCQUEST is ideal for industrial building applications. ADDCQUEST has excellent insulating properties, improves air quality, soaks up moisture and protects from radiation. It can be used as pigmentation for concrete or mortar, plaster...

Carbonised biocoal powder

Perpetual Carbon powder exhibits good potential to act as a drop-in replacement for a variety of different fossil fuels. It can be used as a substitute for PCI coal (Pulverized Coal Injection) in blast furnace...

AddQuest biochar chips

ADDCQUEST is ideal for industrial building applications. ADDCQUEST has excellent insulating properties, improves air quality, soaks up moisture and protects from radiation. It can be used as pigmentation for concrete or...

This section contains a selection of our safety data sheets (SDS). The SDS include information such as the properties of each chemical, the physical and environmental health hazards, protective measures and safety precautions for handling, storing, and transporting the chemical.

For all our technical papers, please visit our Knowledge page.

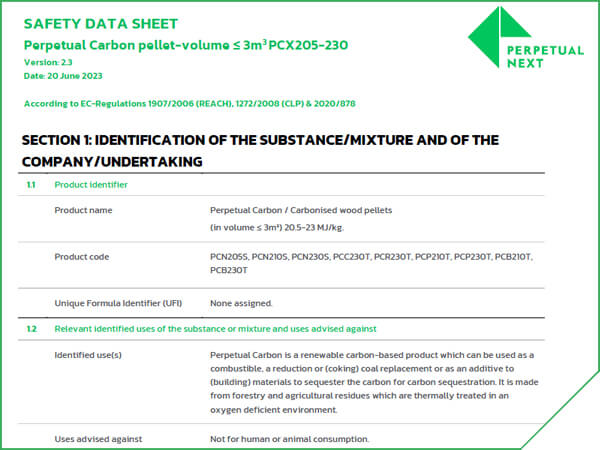

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in Pellet form with a volume ≤ 3 m3 with type number references PCX205-230. It includes the properties of each chemical, the physical, health, and environmental health hazards, protective measures and safety precautions for handling, storing, and transporting this material.

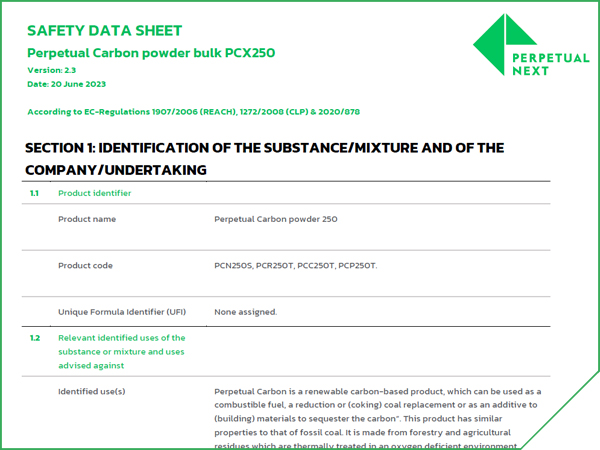

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in powder form in bulk volume. It includes information such as the properties of each chemical, the physical, health, and environmental health hazards, protective measures, and safety precautions for handling, storing, and transporting this material.

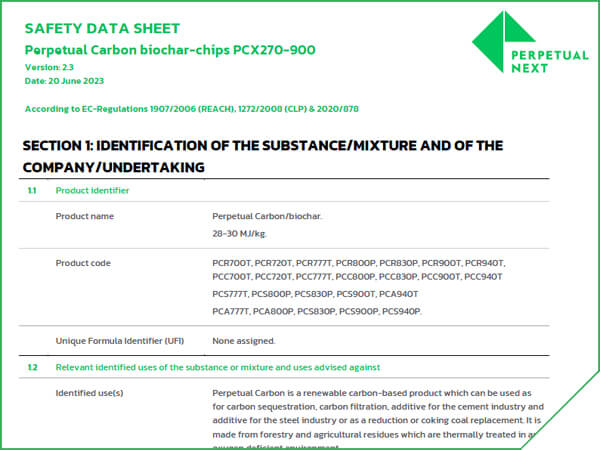

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon biochar-chips with a volume ≤ 3 m3 with typenumber references PCX270-900. It includes the properties of each chemical, the physical, health, and environmental health hazards, protective measures, and safety precautions for handling, storing, and transporting this material.