Steel is a sustainable material and a vital material to society - one that is durable, sustainable, and a critical component in our transition to more energy-efficient and environmentally friendly materials. Steel has the potential to significantly reduce CO₂ emissions, with estimates suggesting a 7-10% decrease in energy-related CO₂.

At Perpetual Next, we support the steel industry in its transition to a circular and fossil-free model. This is not only an environmental challenge, but a key factor in your company's success and competitiveness in the marketplace.

"Perpetual Next’s technologies are a perfect fit with our focus on achieving demonstrable progress towards net-zero steel."

- Manfred Van Vlierberghe - CEO ArcelorMittal Belgium

Does your company make steel via blast furnace/basic oxygen furnace (BF-BOF), direct reduction/electric arc furnace (DRI-EAF) or melting of scrap metal in electric arc furnace (EAF)?

The carbon atom is an essential element in steel production. In then transition phase from fossil to fossil free, you must make important decisions to safeguard the future of your company and perpetuate your business.

Our renewable carbon products are developed and produced from sustainably sourced organic residues. It contains fewer contaminants than fossil carbon sources and can be used directly without CAPEX intensive modifications of the production unit. We have solutions for different steelmaking variants, developed and tested with leading steel producers.

With our support you can now reduce the carbon footprint of your plant.

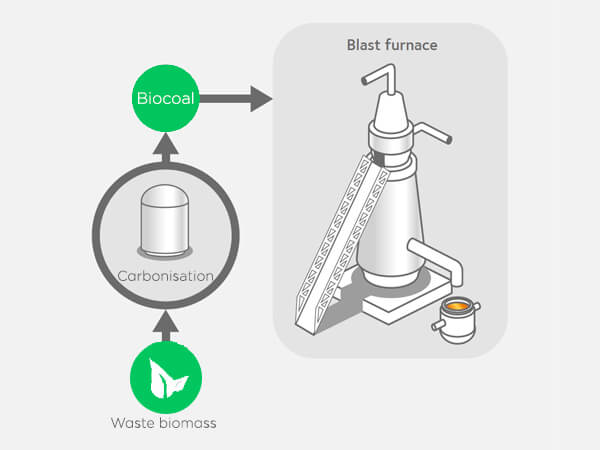

Carbonisation is the thermochemical conversion of biomass in an oxygen-free environment. It generates a solid material with increased energy density and carbon content. Syngas is also obtained as by-product.

Our C-Vertr technology uses indirect heated reactor technologies for carbonisation, where the feedstock is thermally treated. The obtained product is a sustainable solid material (Perpetual Carbon) that has similar properties to fossil carbon.

Perpetual Next is technology partner in the Torero project (TORrefying wood with Ethanol as a Renewable Output).

Torero: reducing iron ore with biocarbon

Today, most blast furnaces reduce iron ore using a high temperature, synthetic gas derived from coal and coke. This makes the modern blast furnace with its high-tech gasification technology ideal for replacing fossil fuels with ‘circular carbon’ inputs, such as organic waste, including agricultural and forestry residues, and even waste plastics.

The Torero project targets the production of biocoal from waste wood to displace the fossil fuel coal that is currently injected into the blast furnace.

Perpetual Next is as technology supplier part of a full value chain consisting of industry partners ArcelorMittal and Renewi and two expert research organisations Joanneum Research and Chalmers Technical University.

Organic residues to biocoal

In Vägari, Estonia, a biocoal plant based on Perpetual Next's C-Vertr V technology has been under construction since 2020. A total of eight to ten reactors will be installed in the plant, capable of producing 120 kilotons of biocoal per year.

Organic residues, B-wood & SRF to biocoal

In Dilsen-Stokkem, Belgium, a biocoal plant based on Perpetual Next's C-Vertr R technology has been in operation since 2010. This site has a nameplate capacity of 27,700 t/y of biocoal output.

This section contains a selection of our most relevant technical papers in the field of carbonisation for this segment application. These technical papers are mostly papers from our own Perpetual Next experts.

For all our technical papers, please visit our Knowledge page.

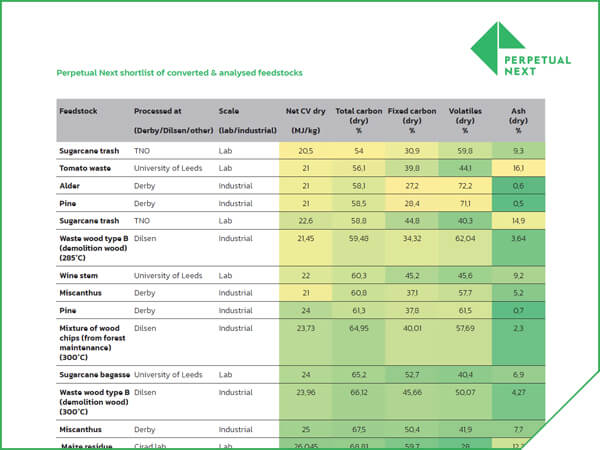

Tabel

At Perpetual Next, we continue to analyse different types of feedstocks, options from different feedstock baskets, with different properties. All feedstocks have their advantages, it all depends on which bias you look at an opportunity. This document is the shortlist of feedstocks we have looked at so far in more detail.

An overview of different kind of feedstock in the carbonisation process

Different kind of biomass containing feedstocks have been tested by Perpetual Next Dilsen-Stokkem: mixed woodchips, acacia wood, eucalyptus wood, used untreated pine/spruce wood, treated used mixed wood, blends of...

Producing optimal pellet quality with minimal energy consumption & wear on parts

To store and to transport carbonised material safe and at lower costs users request to densify this material by pelletizing. However it has become clear, that this densification process is rather critical and expensive...

This section contains a selection of the most relevant scientific papers in the field of carbonisation for this segment application. These scientific papers are made by scientist in the field of carbonisation. So these downloads are conducted by others.

For all our technical papers, please visit our Knowledge page.

Daya Ram Nhuchhen, Prabir Basu and Bishnu Acharya

Biomass is a versatile energy resource that could be used as a sustainable energy resource in solid, liquid and gaseous form of energy sources. Torrefaction is an emerging thermal biomass pretreatment method...

F. Cirilli, G. Baracchini, L. Bianco

Fossil sources are extensively used in the Electric Arc Furnaces (EAF), to provide energy (in addition to electricity) or in general for process needs (to provide carbon to steel bath and promote slag foaming which...

Hannu Suopajärvi, EvaPongrácz, TimoFabritius

Steel is one of the most important materials used in modern society. The majority of the steel produced today is based on the use of virgin raw materials such as iron ore and fossil-based energy sources such as...

This section contains our position papers. These position papers are documents that present an arguable opinion in the field of carbonisation.

For all our technical papers, please visit our Knowledge page.

Part of discussion artickels about carbonisation of low-value bio-residual flows for replacement of fossil carbo

Nowadays it is widely accepted that the era of fossil carbon must end and therefore an important and urgent transition to a fossil-free industry needs to take place. Carbonised solids are perhaps the most known ...

External paper

Torrefaction, in the view of the authors, is the term that describes thermal treatment of any solid biomass in an inert atmosphere with the aim to separate a part or all volatile matters in solid biomass and to concentrate carbon...

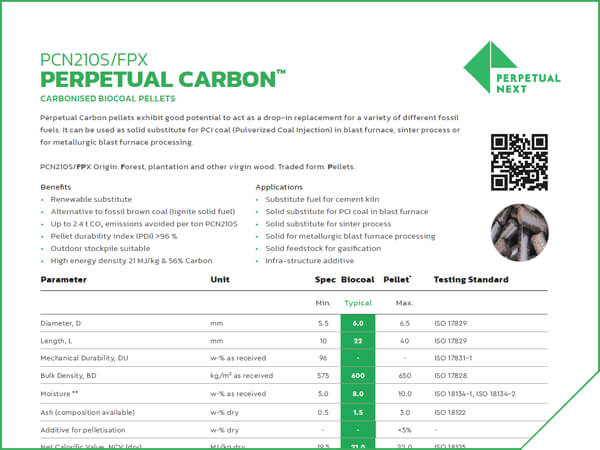

This section contains a selection of our specification (spec) sheets. A spec sheet, or data sheet, summarizes the performance and other characteristics of a specific form and grade of Perpetual Carbon.

For all our technical papers, please visit our Knowledge page.

Carbonised biocoal pellets

Perpetual Carbon pellets exhibit good potential to act as a drop-in replacement for a variety of different fossil fuels. It can be used as solid substitute for PCI coal (Pulverized Coal Injection) in blast furnace, sinter process or for...

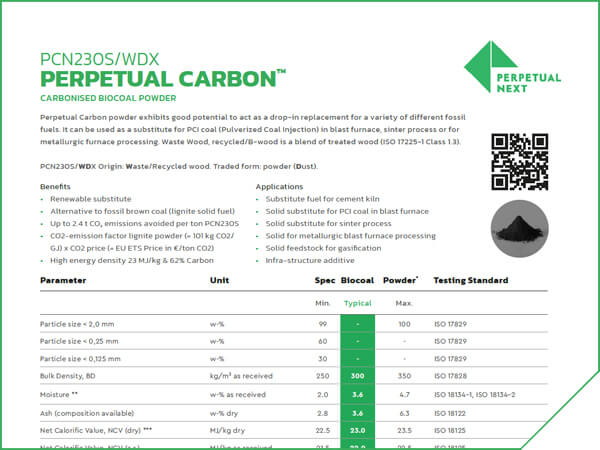

Carbonised biocoal powder

Perpetual Carbon powder exhibit good potential to act as a drop-in replacement for a variety of different fossil fuels. It can be used as a substitute for PCI coal (Pulverized Coal Injection) in blast furnace, sinter process or for...

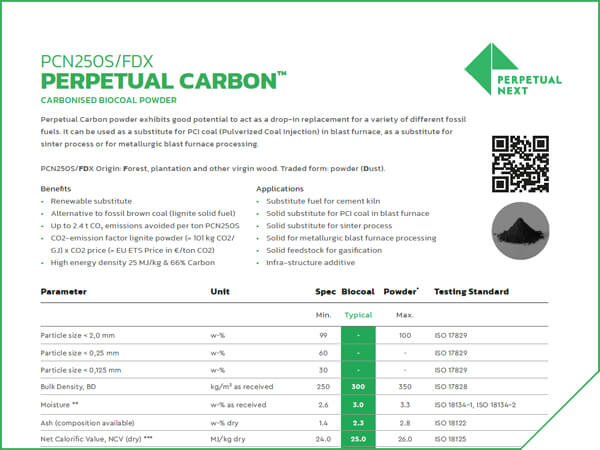

Carbonised biocoal powder

Perpetual Carbon powder exhibits good potential to act as a drop-in replacement for a variety of different fossil fuels. It can be used as a substitute for PCI coal (Pulverized Coal Injection) in blast furnace...

This section contains a selection of our safety data sheets (SDS). The SDS include information such as the properties of each chemical, the physical and environmental health hazards, protective measures and safety precautions for handling, storing, and transporting the chemical.

For all our technical papers, please visit our Knowledge page.

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in Pellet form with a volume ≤ 3 m3 with type number references PCX205-230. It includes the properties of each chemical, the physical, health, and environmental health hazards, protective measures and safety precautions for handling, storing, and transporting this material.

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in pellet form in bulk volume with type number references PCX205-230. It includes the properties of each chemical, the physical, health, and environmental health hazards, protective measures, and safety precautions for handling, storing, and transporting this material.

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in powder form in bulk volume. It includes information such as the properties of each chemical, the physical, health, and environmental health hazards, protective measures, and safety precautions for handling, storing, and transporting this material.