Cement is the most widely utilised artificial material in the world and is second only to water as the most-consumed resource on the planet.

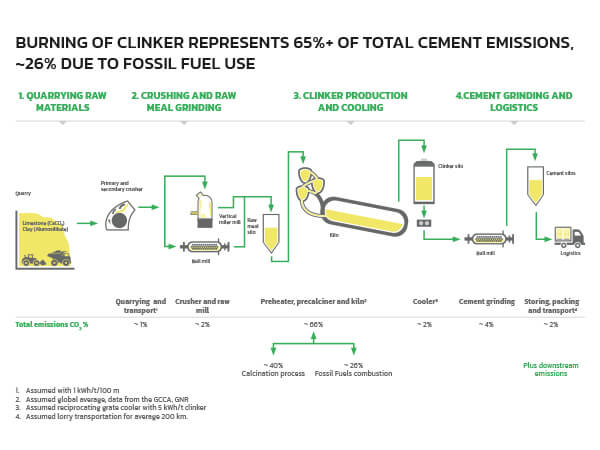

This also presents a significant opportunity for the cement industry to play a leading role in reducing CO₂ emissions (roughly 8% of the world's total). At Perpetual Next, we understand the magnitude of this challenge and the need for a comprehensive approach for companies in the industry.

We consider it our 'beautiful' task to support the cement sector in its journey towards a Net Zero future. This is not only an environmental responsibility, but a critical factor in enhancing the competitiveness and longevity of your company.

So let's connect.

“Our cement production plant has performed trials where biocoal has been used to substitute fossil fuel in the clinker burning process.

Perpetual Next has supported the plant from the start.

The results from trials have been positive: maintained performance in pyro process, the clinker quality is good, cement test done on produced clinker, quality good and within standard limits.“

- Project Manager of Cement Production Plant

Are you a producer of clinker-based cement? Are you looking for solutions on clinker replacement, like calcined clay? In this transition phase between traditional emission-intensive production towards Net Zero, you are faced with important decisions to safeguard the future of your company and perpetuate your business.

Perpetual Next’s renewable carbon products are developed and produced from sustainable and circular sources, such as demolition wood and forestry and agricultural residues. They contain fewer contaminants than fossil carbon sources and can be used directly without CAPEX intensive modifications of the production unit. We have the solution for different production variants of construction materials.

With our support you can now reduce your carbon footprint.

Examples of fossil carbon avoidance applications:

Example of carbon removal applications:

We seek to understand your process and your challenge and work in close collaborations to develop tailor made solutions. Thanks to our advanced R&D, we can provide solutions in the form of renewable carbon products and carbonisation technologies for your production process.

Cement production based in calcination reactions practices will continue to release CO2 due to its fundamental chemistry. We have solutions to make your process more sustainable.

Organic residues to biocoal

In Vägari, Estonia, a biocoal plant based on Perpetual Next's C-Vertr V technology has been under construction since 2020. A total of eight to ten reactors will be installed in the plant, capable of producing 120 kilotons of biocoal per year.

Organic residues, B-wood & SRF to biocoal

In Dilsen-Stokkem, Belgium, a biocoal plant based on Perpetual Next's C-Vertr R technology has been in operation since 2010. This site has a nameplate capacity of 27,700 t/y of biocoal output.

This section contains a selection of our most relevant technical papers in the field of carbonisation for this segment application. These technical papers are mostly papers from our own Perpetual Next experts.

For all our technical papers, please visit our Knowledge page.

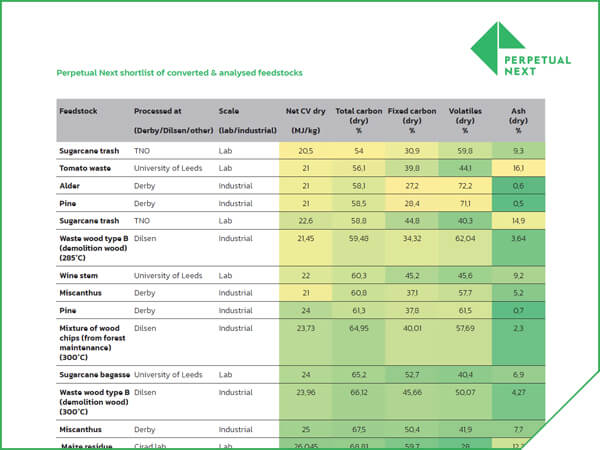

Tabel

At Perpetual Next, we continue to analyse different types of feedstocks, options from different feedstock baskets, with different properties. All feedstocks have their advantages, it all depends on which bias you look at an opportunity. This document is the shortlist of feedstocks we have looked at so far in more detail.

Period 2011-2013

Solid recovered Fuel (SRF) is a fluff material obtained from non-hazardous domestic and industrial waste. This waste has been made smaller, dried and inerts, ferro and non ferro has been removed as good as possible. Also...

This section contains a selection of the most relevant scientific papers in the field of carbonisation for this segment application. These scientific papers are made by scientist in the field of carbonisation. So these downloads are conducted by others.

For all our technical papers, please visit our Knowledge page.

Daya Ram Nhuchhen, Prabir Basu and Bishnu Acharya

Biomass is a versatile energy resource that could be used as a sustainable energy resource in solid, liquid and gaseous form of energy sources. Torrefaction is an emerging thermal biomass pretreatment method...

Piotr Piersa, Hilal Unyay, Szymon Szufa, ...

Major efforts are currently being made in the research community to address the challenges of greenhouse gas emissions from fossil fuel combustion by using lignocellulosic biomass, agricultural waste, and...

D. Suarez-Rieraa, L. Restuccia, G.A. Ferro

The organic waste management is a most current topic, because its processing and degradation it is responsible for emissions of methane and other greenhouse gases, leading to serious environmental problems...

This section contains our position papers. These position papers are documents that present an arguable opinion in the field of carbonisation.

For all our technical papers, please visit our Knowledge page.

External paper

Lime and limestone are basic enabling compounds which are necessary to many other industrial value chains, such as air pollution control, purifying drinking water, wastewater, support sustainable agriculture, enable...

External paper

Torrefaction, in the view of the authors, is the term that describes thermal treatment of any solid biomass in an inert atmosphere with the aim to separate a part or all volatile matters in solid biomass and to concentrate carbon...

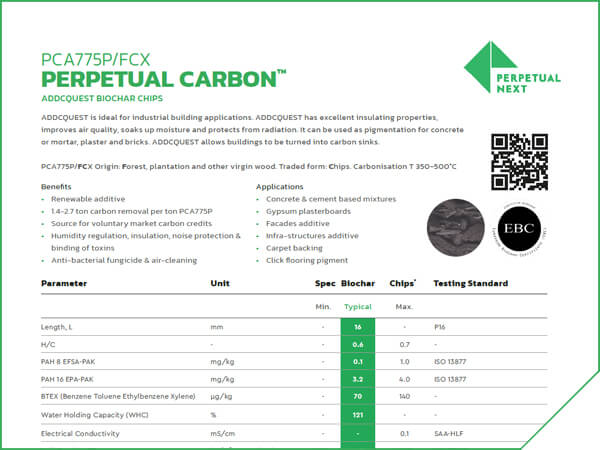

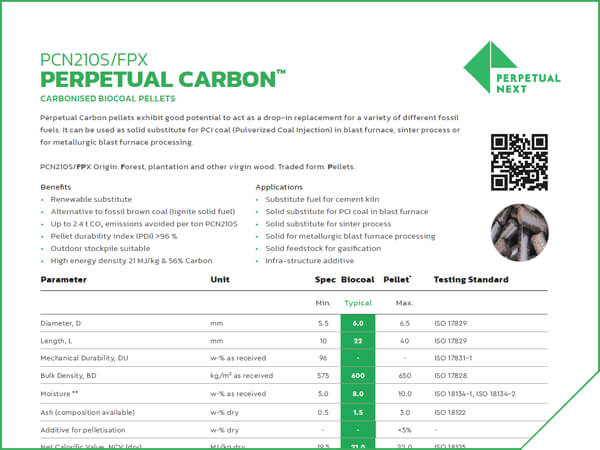

This section contains a selection of our specification (spec) sheets. A spec sheet, or data sheet, summarizes the performance and other characteristics of a specific form and grade of Perpetual Carbon.

For all our technical papers, please visit our Knowledge page.

AddQuest biochar chips

ADDCQUEST is ideal for industrial building applications. ADDCQUEST has excellent insulating properties, improves air quality, soaks up moisture and protects from radiation. It can be used as pigmentation for concrete or mortar, plaster...

Carbonised biocoal pellets

Perpetual Carbon pellets exhibit good potential to act as a drop-in replacement for a variety of different fossil fuels. It can be used as solid substitute for PCI coal (Pulverized Coal Injection) in blast furnace, sinter process or for...

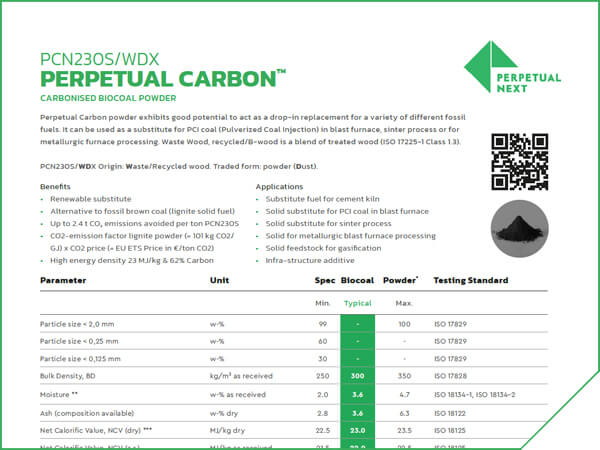

Carbonised biocoal powder

Perpetual Carbon powder exhibit good potential to act as a drop-in replacement for a variety of different fossil fuels. It can be used as a substitute for PCI coal (Pulverized Coal Injection) in blast furnace, sinter process or for...

This section contains a selection of our safety data sheets (SDS). The SDS include information such as the properties of each chemical, the physical and environmental health hazards, protective measures and safety precautions for handling, storing, and transporting the chemical.

For all our technical papers, please visit our Knowledge page.

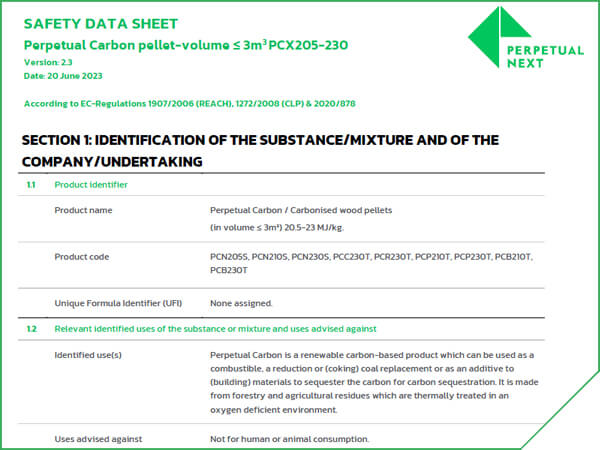

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in Pellet form with a volume ≤ 3 m3 with type number references PCX205-230. It includes the properties of each chemical, the physical, health, and environmental health hazards, protective measures and safety precautions for handling, storing, and transporting this material.

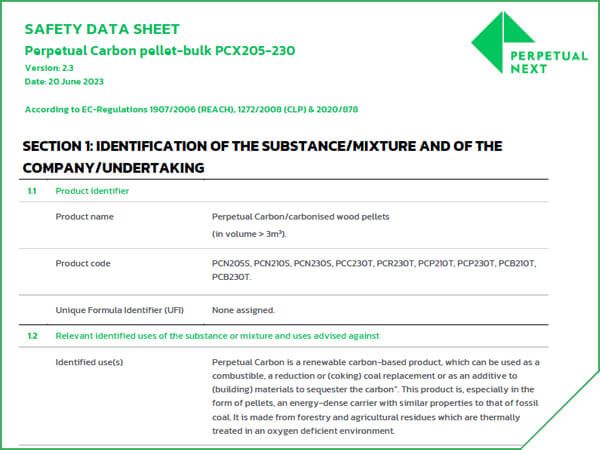

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in pellet form in bulk volume with type number references PCX205-230. It includes the properties of each chemical, the physical, health, and environmental health hazards, protective measures, and safety precautions for handling, storing, and transporting this material.

Safety data sheet

This SDS (formerly MSDS or Material Safety Data Sheet) is about Perpetual Carbon, in powder form in bulk volume. It includes information such as the properties of each chemical, the physical, health, and environmental health hazards, protective measures, and safety precautions for handling, storing, and transporting this material.